Draf-flight conveyor is a conveyor that convey like dust, granules and bulk materials such as bulk continuous conveyor. It can be horizontal, inclined and vertical transportation, the materials are operated with a driving force in hanging boards; Draf-flight conveyor is designed by using the bulk materials with the characteristics of internal friction and lateral pressure; Draf-flight conveyor has a simple structure, small size, good sealing performance, installation and maintenance more convenient, more feeding, and more flexible process layout; it is widely used in chemical industry, building materials, metallurgy, electric power, food, light industry and transportation and other departments; Draf-flight conveyor is used with the wear-resistant lining structure both at the bottom and side with some other wear-resistant lining to ensure equipment’s casing from wear and extend equipment life.

Draf-flight conveyor can transport materials in horizontal, inclined or vertical cases. When materials are transported at the horizontal or small angle (angle less than 20 °), the materials are received force by draf-flight’s chain in the direction of motion. When the internal friction in the material layer is greater than the outer friction between the materials and slot wall, the materials is moved forward with the draf-flight’s chain. When the ratio of material layer height and casing width is satisfied a certain requirement, the materials are stable; In vertical transportation, because the materials have a skew back feature, materials in closed casing are pushed by the draf-flight’s chain in the direction of motion and received resistance from constantly feeding and prevent the materials on above from slipping and then create the transverse lateral pressure and increase the materials internal friction. When the internal friction in the material layer is greater than the outer friction between the materials and slot wall and the materials deadweight, the materials are conveyed upward with draf-flight chain and formed a continuous material flow.

Draf-flight conveyor transport capacity according to different specifications and models have MS250, MS400, MS500, MS630, MS800, MS1000, MS1200, MS1400, MS1600, MS2000, If the transmission capacity is 10m ³ / h ~ 300 m³ / h; When you elect the type under MS500, use the single-chain form of welding draf-flight and when you elect the type above MS630, use the double-chain draf-flight structure for greater throughput .

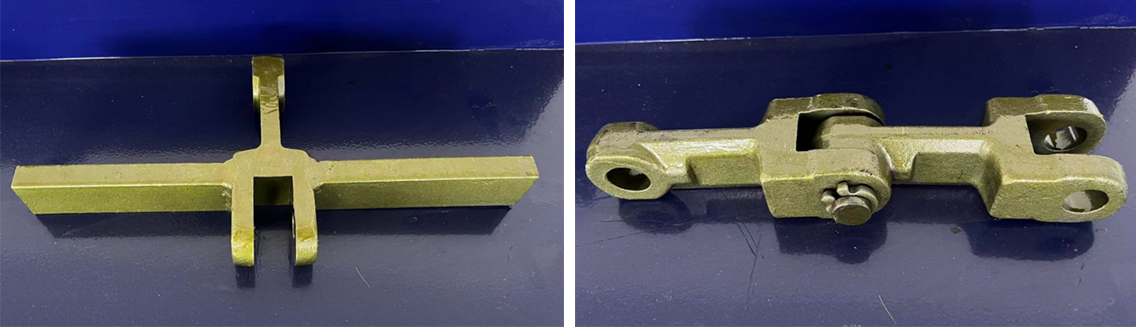

Draf-flight chain use high-quality structural steel with two forms: precision casting and precision forging. When the conveying material temperature is very high, appropriately use precision casting chain. Because precision casting can guarantee flight and chain be together without welding molding; When the material temperature is not particularly high also the transmission is large, suitable for precision forging with the structure of the draf-flight chain. Chain is required to use advanced heat treatment process to protect the chain of integrated mechanical performance and reliability. Chain specification is well-matched with draf-flight conveyor and according to the different length of the chain choose different intensity chain. Specification as below.

Table -1

|

Type |

102A |

125A |

142A |

142B |

150A |

160A |

216A |

250A |

|

Break load

(Kn) |

180 |

200 |

300 |

450 |

300 |

350 |

600 |

700 |

|

W

(mm) |

28 |

36 |

42 |

62 |

36 |

42 |

59 |

70 |

|

T

(mm) |

6.5 |

10 |

12 |

16.5 |

13 |

13 |

19 |

18 |

|

H

(mm) |

36 |

35 |

50 |

50 |

49 |

44.5 |

75 |

75 |

|

M

(mm) |

12 |

15 |

18.7 |

28.5 |

15 |

19.5 |

26 |

32 |

|

P

(mm) |

102 |

125 |

142 |

142 |

150 |

160 |

216 |

150 |

|

D

(mm) |

14 |

16 |

25 |

25 |

25 |

20 |

35 |

32 |

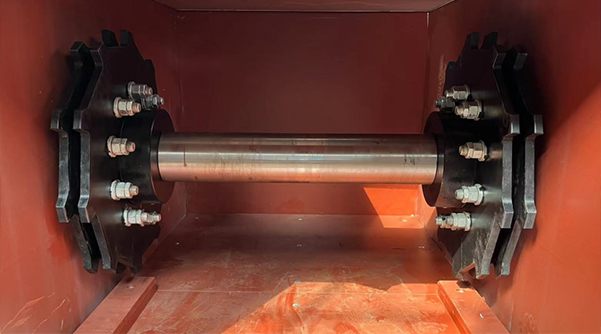

Draf-flight conveyor sprocket wheel is according to humanization design, Sprocket wheel from the wheel rim and the core is made by high-strength bolts connection and wheel rim used high wear resistant structural steel. After induction hardening, the hardening layer thickness of 5mm or more and to ensure equipment wear resistance ; round core with a relatively low cost of steel or forged parts, wheel rim and the wheel core through high-strength bolt connection, not only guarantee the sprocket wear resistance and economy, but also avoiding the trouble with replacement of wearing sprocket wheel and making lower maintenance costs.

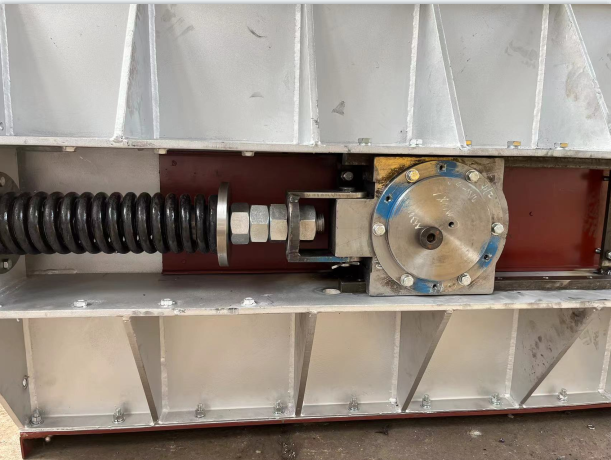

Draf-flight conveyor tension divided into two forms, one is the form of tail tension, thread tension by screw or spring tension with the form; another is the form of head tension which is a casing on the head with two additional adjustment sprocket wheel to adjust the chain tension level; tail tension applied to the equipment with horizontal or small inclined angle and head tension applied to vertical or a big angle for transportation equipment.

|

标准条件下的输送能力 |

||||||||||

|

宽度 |

槽 体 |

物料 |

刮板 |

理论能力 m3/h |

||||||

|

|

宽度 B |

高度 H |

S |

高度 h |

速度 m/s |

|||||

|

mm |

mm |

mm |

mm |

mm |

0.05 |

0.1 |

0.15 |

0.2 |

0.25 |

0.3 |

|

250/1 |

306 |

515 |

100 |

50 |

5.5 |

11.0 |

16.5 |

22.0 |

27.5 |

33.0 |

|

400/1 |

456 |

515 |

150 |

50 |

12.5 |

25.0 |

37.5 |

50.0 |

62.5 |

75.0 |

|

|

|

645 |

|

50 |

|

|

|

|

|

|

|

630/1 |

686 |

515 |

170 |

50 |

20.0 |

40.0 |

60.0 |

80.0 |

100.0 |

120.0 |

|

630/2 |

|

645 |

|

50 |

|

|

|

|

|

|

|

800/2 |

856 |

515 |

200 |

50 |

29.5 |

59.0 |

88.5 |

118.0 |

147.5 |

|

|

|

|

645 |

230 |

60 |

34.5 |

69.0 |

103.0 |

138.0 |

172.5 |

|

|

1000/2 |

1056 |

645 |

230 |

60 |

49.5 |

99.0 |

148.5 |

198.0 |

247.5 |

|

|

|

|

775 |

280 |

60 |

51.5 |

103.0 |

154.5 |

206.0 |

257.5 |

|

|

1200/2 |

1256 |

645 |

230 |

60 |

50.5 |

101.0 |

151.5 |

202.0 |

310.0 |

|

|

|

|

775 |

280 |

60 |

62.0 |

124.0 |

186.0 |

248.0 |

|

|

|

1400/2 |

1456 |

645 |

230 |

60 |

59.0 |

118.0 |

177.0 |

236.0 |

|

|

|

|

|

775 |

280 |

60 |

71.5 |

143.0 |

214.5 |

286.0 |

|

|

|

1600/2 |

1656 |

775 |

280 |

80 |

81.5 |

163.0 |

244.5 |

326.0 |

|

|

|

1800/2 |

1856 |

775 |

280 |

80 |

91.5 |

183.0 |

274.5 |

|

|

|

|

2000/2 |

2056 |

775 |

280 |

80 |

102.0 |

204.0 |

306.0 |

|

|

|

|

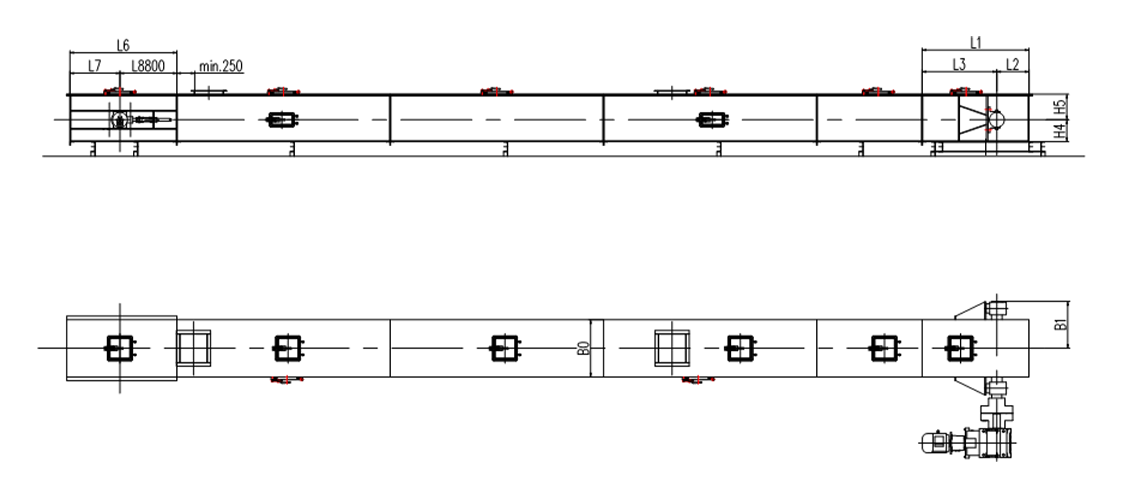

B |

链条 |

节距 |

齿数 |

轴承Φ |

L1 |

L2 |

L3 |

L6 |

L7 |

L8 |

H4 |

H5 |

B0 |

B1 |

|

250 |

40/20 |

142 |

6 |

65/50 |

1000 |

300 |

700 |

1000 |

600 |

400 |

198 |

265 |

413 |

510 |

|

250 |

50/25 |

142 |

6 |

65/50 |

1000 |

300 |

700 |

1000 |

600 |

400 |

198 |

265 |

413 |

510 |

|

250 |

50/25 |

142 |

8 |

80/60 |

1000 |

300 |

700 |

1000 |

575 |

425 |

258 |

310 |

413 |

570 |

|

315 |

50/25 |

142 |

6 |

65/50 |

1000 |

300 |

700 |

1000 |

600 |

400 |

198 |

265 |

481 |

542 |

|

315 |

50/25 |

142 |

8 |

80/60 |

1000 |

300 |

700 |

1000 |

575 |

425 |

258 |

310 |

481 |

602 |

|

400 |

50/25 |

142 |

6 |

65/50 |

1000 |

300 |

700 |

1000 |

600 |

400 |

198 |

265 |

566 |

585 |

|

400 |

50/25 |

142 |

8 |

80/60 |

1000 |

300 |

700 |

1000 |

575 |

425 |

258 |

310 |

566 |

645 |

|

500 |

50/25 |

142 |

8 |

80/60 |

1000 |

300 |

700 |

1000 |

575 |

425 |

258 |

310 |

666 |

695 |

|

500 |

50/25 |

142 |

8 |

100/75 |

1000 |

300 |

700 |

1000 |

575 |

425 |

258 |

310 |

666 |

755 |

|

630 |

50/25 |

142 |

8 |

100/75 |

1000 |

300 |

700 |

1000 |

575 |

425 |

260 |

310 |

806 |

820 |

|

630 |

60/30 |

200 |

6 |

100/75 |

1000 |

300 |

700 |

1000 |

575 |

425 |

260 |

310 |

806 |

820 |

|

630 |

60/30 |

200 |

8 |

125/75 |

1250 |

350 |

900 |

1000 |

575 |

425 |

360 |

310 |

806 |

870 |

|

630 |

50/25 |

200 |

6 |

125/75 |

1000 |

300 |

700 |

1000 |

575 |

425 |

260 |

310 |

800 |

940 |

|

630 |

50/25 |

200 |

8 |

150/75 |

1250 |

350 |

900 |

1000 |

575 |

425 |

325 |

375 |

800 |

985 |

|

800 |

50/25 |

200 |

6 |

125/75 |

1000 |

300 |

700 |

1000 |

575 |

425 |

260 |

310 |

990 |

1025 |

|

800 |

50/25 |

200 |

8 |

150/75 |

1250 |

350 |

900 |

1000 |

575 |

425 |

325 |

375 |

990 |

1070 |

|

800 |

60/30 |

250 |

6 |

125/75 |

1250 |

350 |

900 |

1000 |

575 |

425 |

325 |

375 |

990 |

1025 |

|

800 |

60/30 |

250 |

8 |

150/75 |

1500 |

450 |

1050 |

1500 |

800 |

700 |

390 |

440 |

990 |

1070 |

|

1000 |

60/30 |

250 |

6 |

125/75 |

1250 |

350 |

900 |

1000 |

575 |

425 |

325 |

375 |

1190 |

1125 |

|

1000 |

60/30 |

250 |

8 |

125/75 |

1500 |

450 |

1050 |

1500 |

800 |

700 |

390 |

440 |

1190 |

1125 |

|

1000 |

60/30 |

250 |

8 |

150/75 |

1500 |

450 |

1050 |

1500 |

800 |

700 |

390 |

440 |

1190 |

1170 |

|

1200 |

60/30 |

250 |

6 |

125/75 |

1250 |

350 |

900 |

1000 |

575 |

425 |

325 |

375 |

1390 |

1225 |

|

1200 |

60/30 |

250 |

8 |

150/75 |

1500 |

450 |

1050 |

1500 |

800 |

700 |

390 |

440 |

1390 |

1270 |

|

1200 |

60/30 |

250 |

8 |

180/75 |

1500 |

450 |

1050 |

1500 |

800 |

700 |

390 |

440 |

1390 |

1335 |